Anubhav Singh

As an avid AI and robotics enthusiast, I am deeply committed to

addressing cutting-edge challenges within the robotics domain, with a profound

focus on shaping our collective future sustainably. My passion is particularly

centered around an array of intricate robotics facets, encompassing robot

dynamics, kinematics, motion planning, control systems, computer vision,

reinforcement learning, and robot navigation. I aspire to contribute

meaningfully to the evolving landscape of robotics through both

theoretical understanding and hands-on application.

Robots:

Experience:

-

Biomechatronics and Energy-Efficient Robotics (BE2R) Lab

RL Engineer (Nov 2024 - Present)

-

Orangewood Labs

Research and Development Engineer, AI & Robotics (Oct 2018 - Dec 2021)

-

Lumiq.ai

AI Engineer Intern (Feb 2018 - Aug 2018)

Education:

- M.Sc. in Robotics and AI (Mechatronics and Robotics), National Research University ITMO, (2024 - Present)

- Bachelor of Technology (B.Tech) in Computer Science and Engineering, Jaypee Institute of Information Technology, (2014 - 2018)

Patents:

- System and/or method for error compensation in mechanical transmissions

Abhinav Kumar, Aditya Bhatia, Akash Bansal, Anubhav Singh,

Ashutosh Prakash, Aman Malhotra, Harshit Gaur, Prasang Srivasatava, Ashish Chauhan

Orangewoodlabs Inc., Publication Number

WO/2021/211578, Publication Date 21.10.2021. (LINK)

Mechanical transmission mechanisms can enable systems to gear actuators up (to operate at higher speeds) or down (to react higher torque loads), but they also can introduce positional error in the system, which negatively impacts system performance. One example of such error is backlash that occurs in gear systems. Backlash is generally known in the mechanical systems as an inefficiency that results from clearance or lost motion in mechanism. Backlash is typically caused by gaps between parts (e.g., the circumferential space between two meshing gear teeth). Hardware solutions have been proposed to correct positional error in mechanical transmission systems. An example hardware solution is a harmonic drive specially designed to reduce or eliminate backlash. While the harmonic drives work well in eliminating error, they are highly complex mechanical systems and, as a result, are very expensive, sometimes prohibitively so for a commercial product. Accordingly, there is a need for an improved technique to correct for cumulative errors in mechanical transmission systems.

Projects:

Github contributions in the last year

Object Segmentation and clustering in realtime 3D Point Clouds using PCL

To get realtime data from d435 Intel realsense camera installed next to the robotic arm and apply techniques like voxel filtering, statistical outlier removal, RANSAC plane segmentation, Euclidean clustering, etc. to locate centroid in each segmented object and eventually publish the detected centroids' coordinated on a ROS publisher of type visualization_msgs/MarkerArray for pick and place action using suction gripper attached on the end effector of the robotic arm.

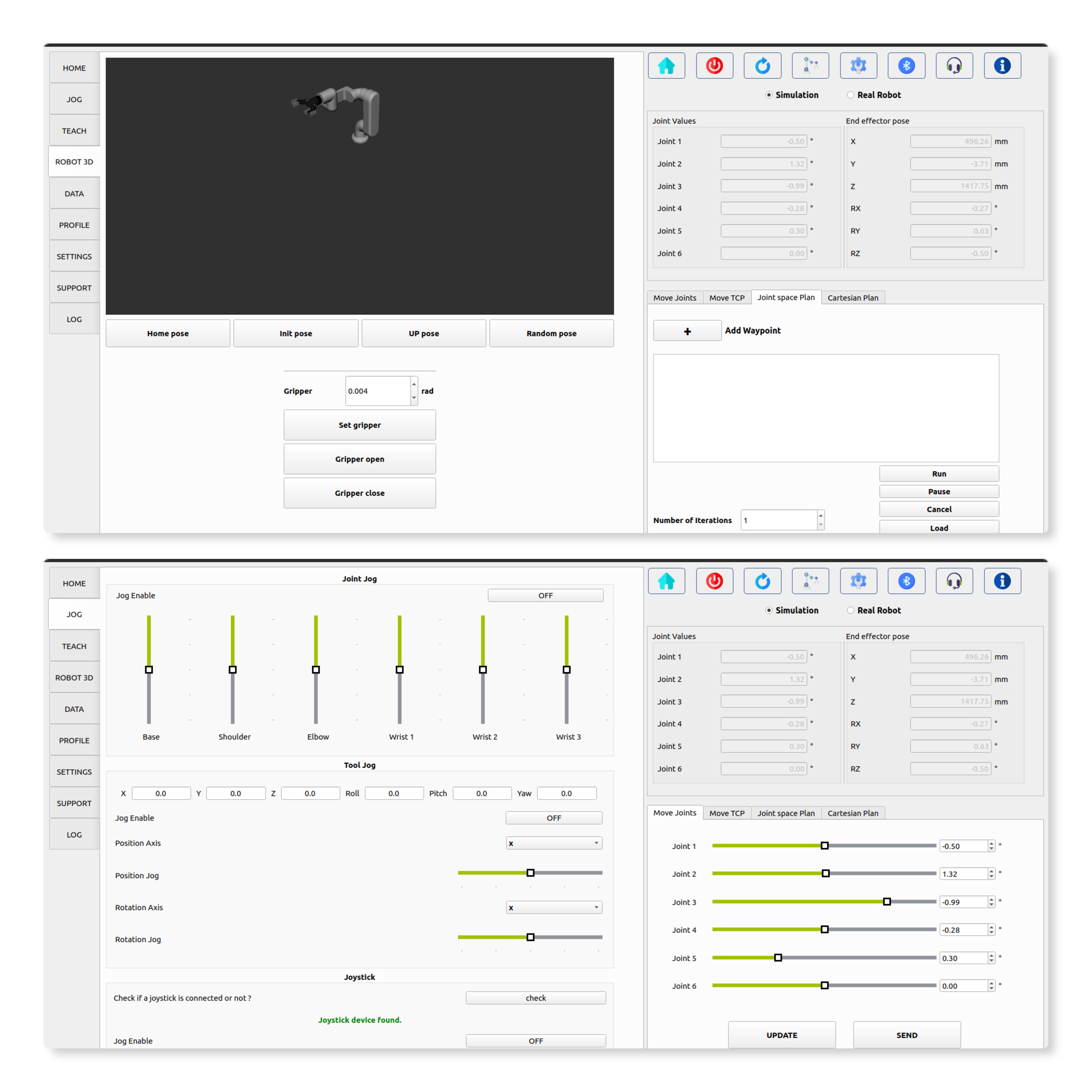

Robotic Arm Software Controller

I built a software controller for a 6-DOF robotic arm using C++ Qt6 framework. The features included are joint based control, trajectory planning (joint space as well as cartesian space), hand teaching (gravity compensation), jogging (joint level, end effector and joystick-based), robot 3D visualization (similar to RViz), sensor data visualization, etc. The backend is using ROS and MoveIt motion planning framework.

6-DOF Robotic Arm Simulation

In this project, I implemented a pick-and-place action using a 6-DOF robotic arm, leveraging the octomap framework. Data from an RGBD camera sensor is used to build a 3D model of the environment around the robotic arm using the ROS octomap library. MoveIt checks for collisions between the robot and the octomap, and generates a motion plan failure if it detects a potential collision. To successfully perform the pick-and-place task, we need to add the object to the planning scene interface to deactivate collision checking between the gripper and the object. Additionally, we must attach the grasped object to the gripper so that MoveIt considers it during collision checking.

Web-based Clickstream Data Analysis using ML

This constituted my undergraduate thesis during the final year of my bachelor's program.

In the dynamic landscape of online shopping, users often engage in product comparisons to make informed decisions. The project involves leveraging clickstream data, a comprehensive log of user activities on the website, to enhance the user experience through a sophisticated recommendation system. The primary goal is to build a robust recommendation system that analyzes clickstream data, identifies similar user profiles, and tailors product recommendations based on user behavior. The system aims to streamline the user's decision-making process by suggesting products from the baskets of similar users and strategically promoting top-selling items.

Certifications:

- Advanced Robotics - (by Indian Institute of Technology Kanpur on NPTEL)

- Aerial Robotics (by University of Pennsylvania on Coursera)

- Industrial Robotics (by Udemy)

- Reinforcement Learning Specialization (by University of Alberta & Alberta Machine Intelligence Institute on Coursera)

- Modern Robotics: Mechanics, Planning, and Control Specialization (by Northwestern University on Coursera)